Due to the impact of the Covid-19 virus personal protective equipment (PPE) and masks have become a part of our everyday lives. Still, PPE serves a vital purpose, besides reducing the transmission of disease, in the workplace and on work sites.

Due to the impact of the Covid-19 virus personal protective equipment (PPE) and masks have become a part of our everyday lives. Still, PPE serves a vital purpose, besides reducing the transmission of disease, in the workplace and on work sites.

According to the U.S. Bureau of Labor Statistics, companies reported 2.8 million workplace-related injuries and illnesses in 2019, with more than a half-million counted as sprains, tears, lacerations, bruises or fractures. Creating a safe workplace environment involves dedication to safety procedures, communication and execution of safety training and inspection.

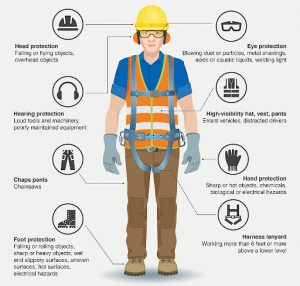

Here a few tips to reduce risk to incident and injury with use of PPE.

Understand the role of your Personal Protective Equipment (PPE).

Each type of PPE is engineered to protect workers against occupational hazards. Safety glasses protect a worker’s eyes from contact by objects and debris. Wraparound goggles provide side protection and some designs will reduce liquid and vapor penetration.

Gloves should be selected carefully for the types of hazards present at the job. Cut-resistant gloves are needed around sharp objects, while chemical-resistant gloves may be needed for lab and manufacturing applications.

Know the situations when PPE should be used.

Following OSHA guidelines is the recommended action for deciding what PPE should be used and when it is required. In any area where workers face airborne debris, safety glasses must be used. Hard hats are required for construction sites and any environments where workers face the hazard of falling objects. Protective apparel, gloves, boots, and respirators are required in many different operations including those that involve chemicals and flame / burn hazards.

Understand the necessary steps in selecting appropriate PPE for your work environment.

Understand the necessary steps in selecting appropriate PPE for your work environment.

You want your PPE to actually provide protection and it will not do this if it is substandard. When you select PPE, you must pay attention to the manufacturer’s ratings and test results. Testing that is conducted in situations that simulate how the garment or other PPE is to be worn in actual workplace scenarios produce the most accurate performance ratings. Make sure that each piece of PPE meets OSHA or NFPA guidelines.

Perform regular maintenance inspections.

Like most equipment, PPE will wear out over time. Many items have expiration dates and must be removed from service after this date. A hard hat should be in use for no longer than five years and the date it is first placed in service should be recorded inside the hat. Some PPE items are required to be replaced after an incident or if it becomes soiled to ensure protection for the wearer is not compromised.

While PPE protects you in the event of an accident, it does not prevent the accident itself. By establishing safety guidelines and training workers in the correct use of PPE, your facility will be safer and any accidents will be less likely to end in injury.

Source: BLS, OSHA, Lakeland Ind